Crystal processing as if yield mattered

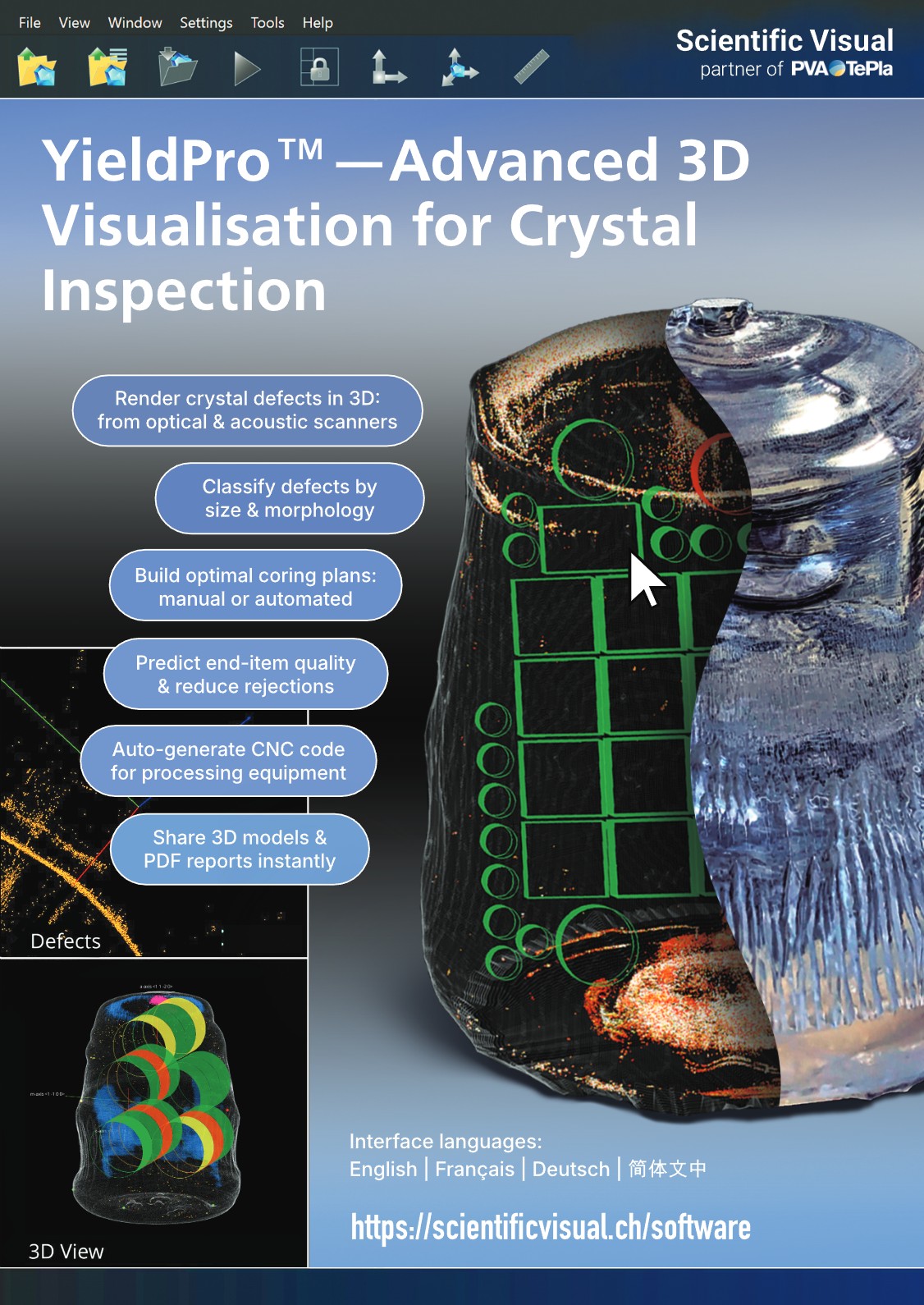

YieldPro™ Optical is a software for analysing 3D inspection data of industrial crystals. It transforms scan data into an interactive 3D model of the crystal – showing crystal geometry, internal defects, defect-free zones and stress maps in one view.

The software guides operators, process engineers and production managers in planning cores and wafers, grading material quality, and documenting QA results. It integrates with Scientific Visual scanners and supports workflows from incoming inspection to final quality reporting and CNC commands.

It is used for quality control in sapphire, spinel, CaF₂, non-linear optical crystals, as well as for optical elements.

Key Benefits

-

Take the guesswork out of crystal production – see clear, actionable quality metrics displayed on your screen

-

Increase usable volume by placing cores and wafers in defect‑free zones

-

Reduce scrap by identifying killer defects before costly processing

-

Standardize grading decisions with configurable and repeatable parameters

-

Shorten production time by exporting ready‑to‑use cutting plans to CNC manufacturing equipment

-

Improve customer engagement by objective defect statistics across batches

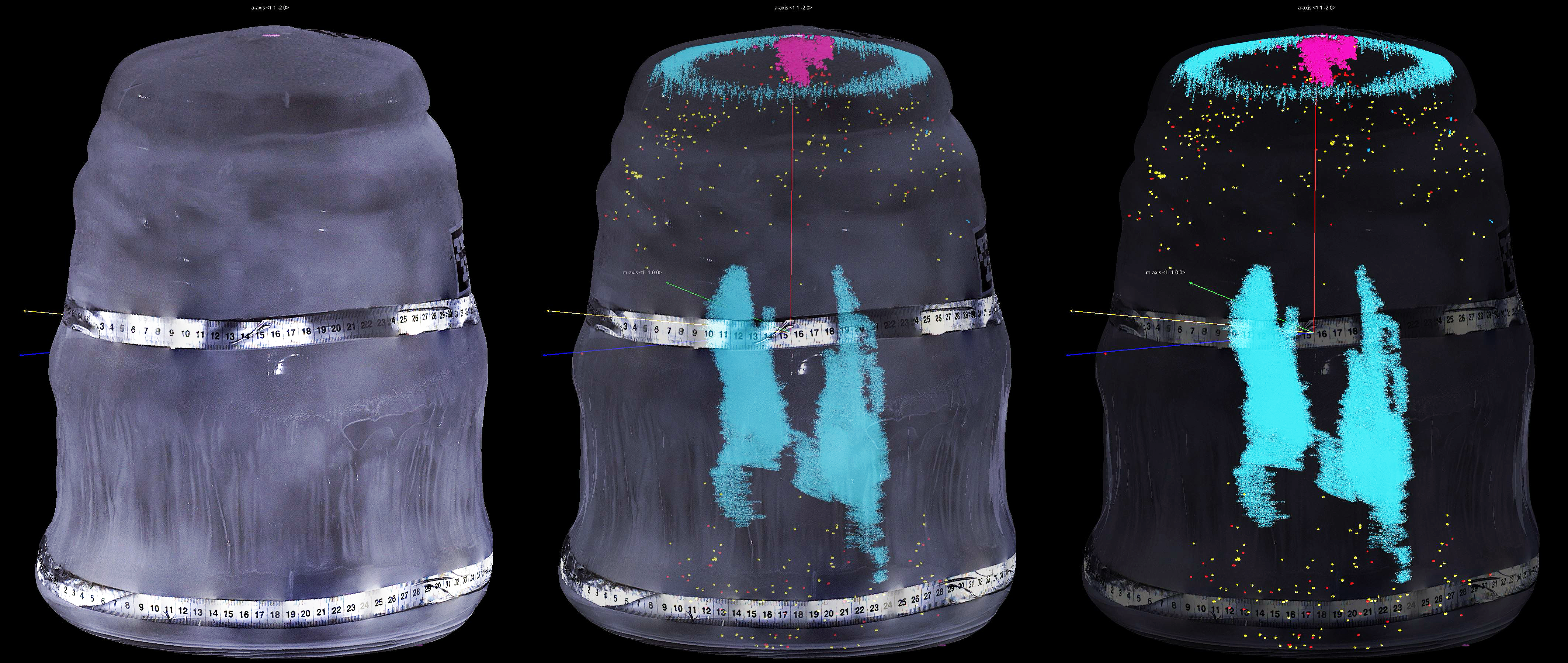

Reveal internal defects with clarity

YieldPro™ provides an interactive 3D view of each crystal, where structural defects can be examined at any depth.

-

Colour-coded defect types: bubbles, inclusions, cracks, micropipes, clouds

-

Precise 3D measurement tools (XYZ location, distance, defect dimensions)

-

Cross-section view along any axis

-

Tune the transparency of skin, texture and volume defects, to see overlapping

-

Export screenshots or full 3D models for reports

This makes it straightforward to locate defect‑free regions or identify zones that must be avoided during cutting.

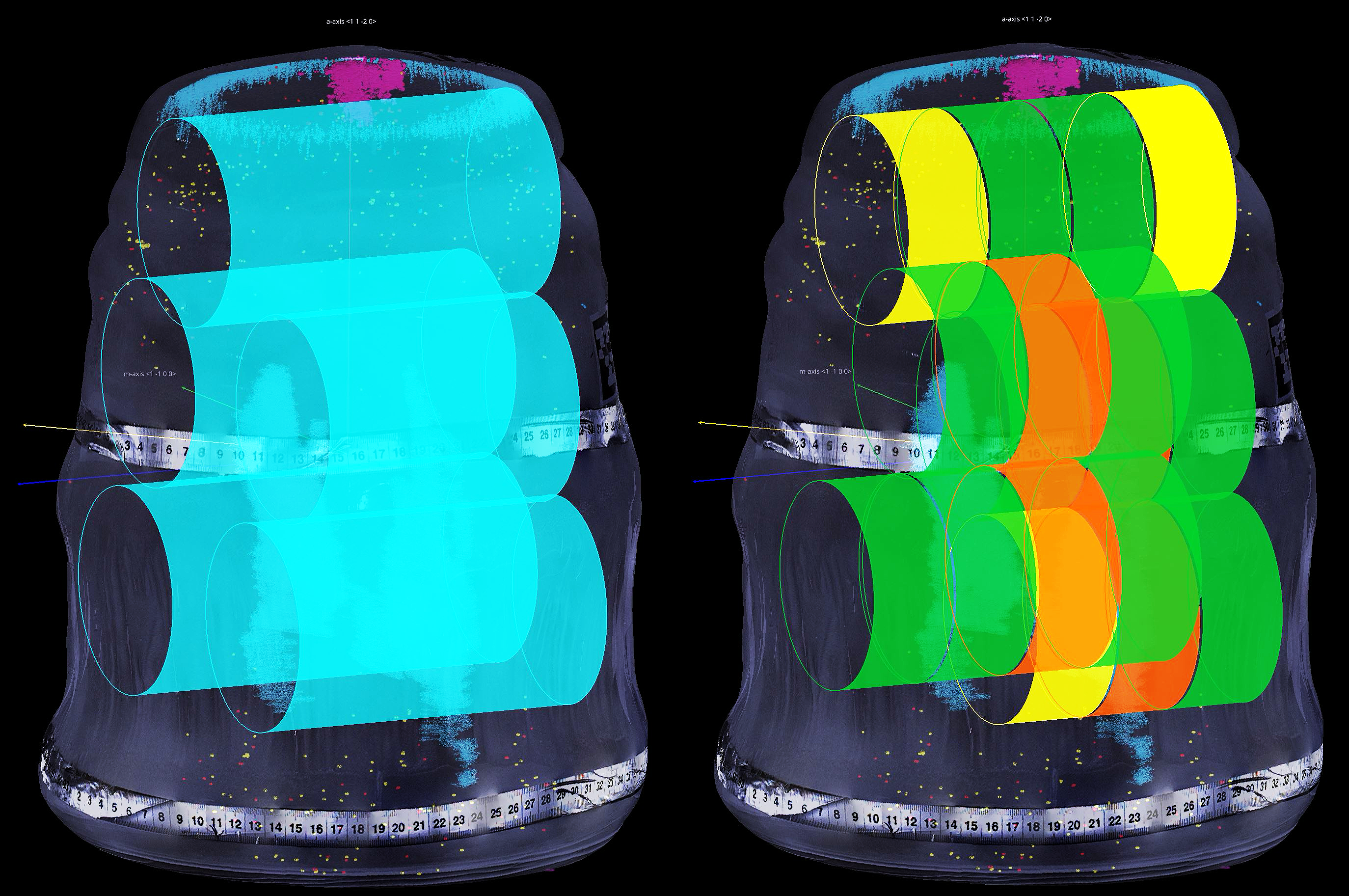

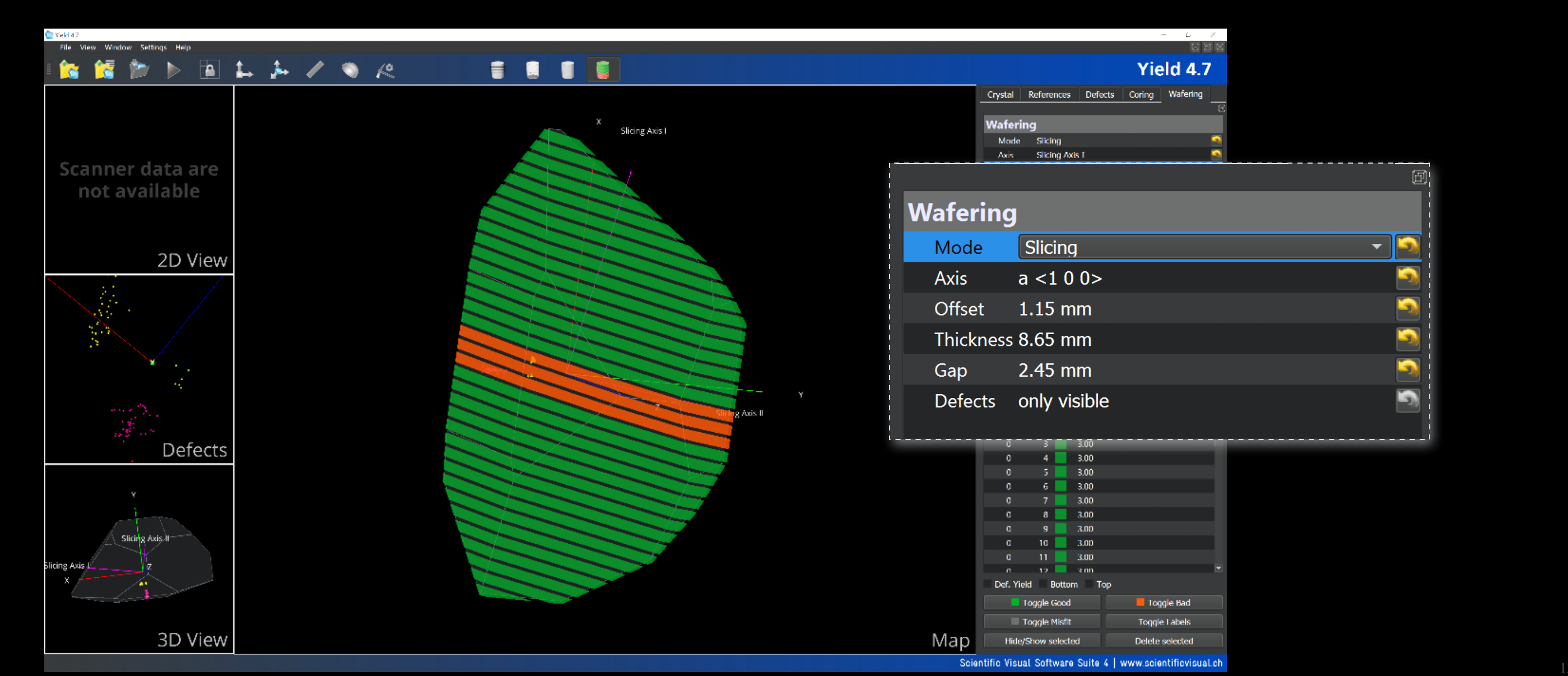

Build optimal processing plan

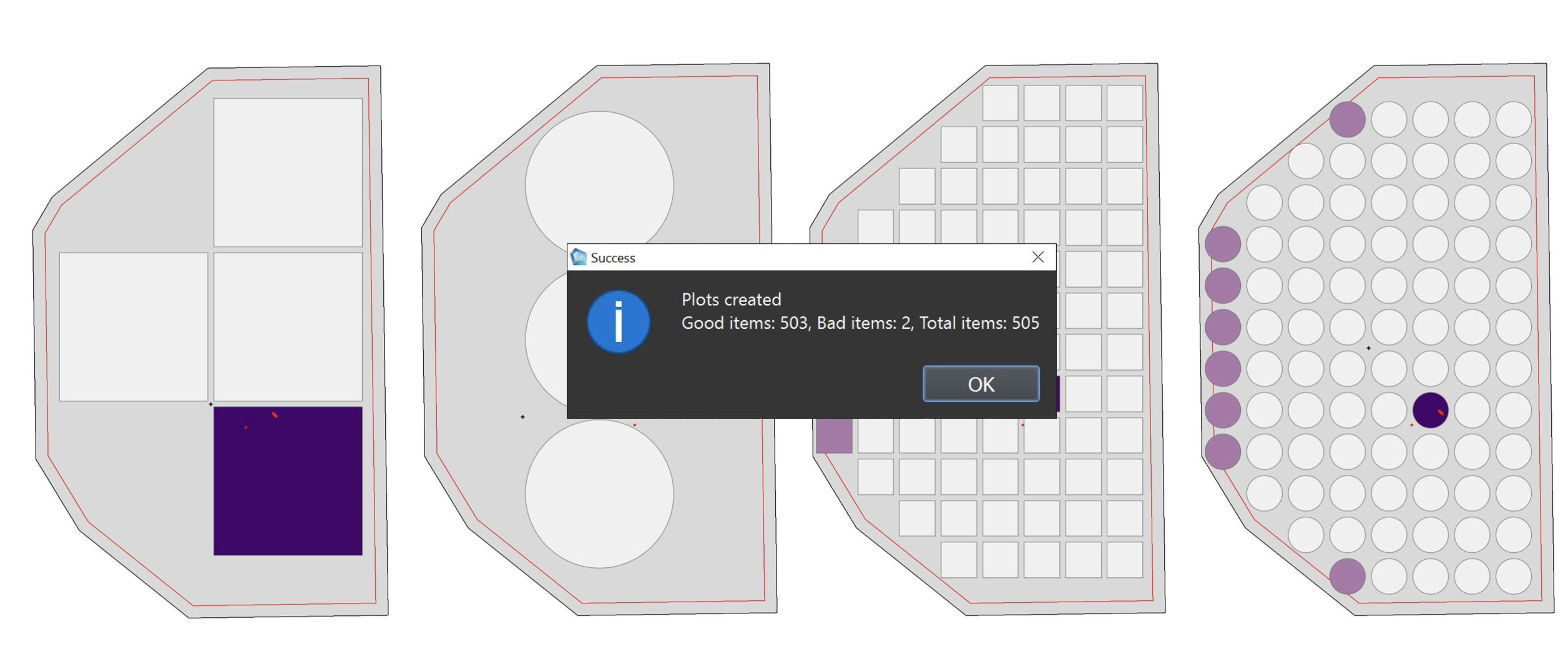

In the yield planning mode, operator places virtual cores, wafers or custom end-items inside the 3D crystal volume. YieldPro checks each proposed shape against the detected defects and estitimates the expected quality level of the resulting parts, and overall yield.

-

Visual wafer maps showing defect-free and defect-affected zones

-

Adjustable tool thickness, kerf loss, position and offsets

-

Simulation of multiple slicing strategies to maximise the number of usable end-items

Compute crystal yield for your application

-

Estimation of wafering and dicing outcome – along crystal axis or custom direction

-

Simulate cutting outcome in a minute

-

Find best crystal for each task – best for stock management

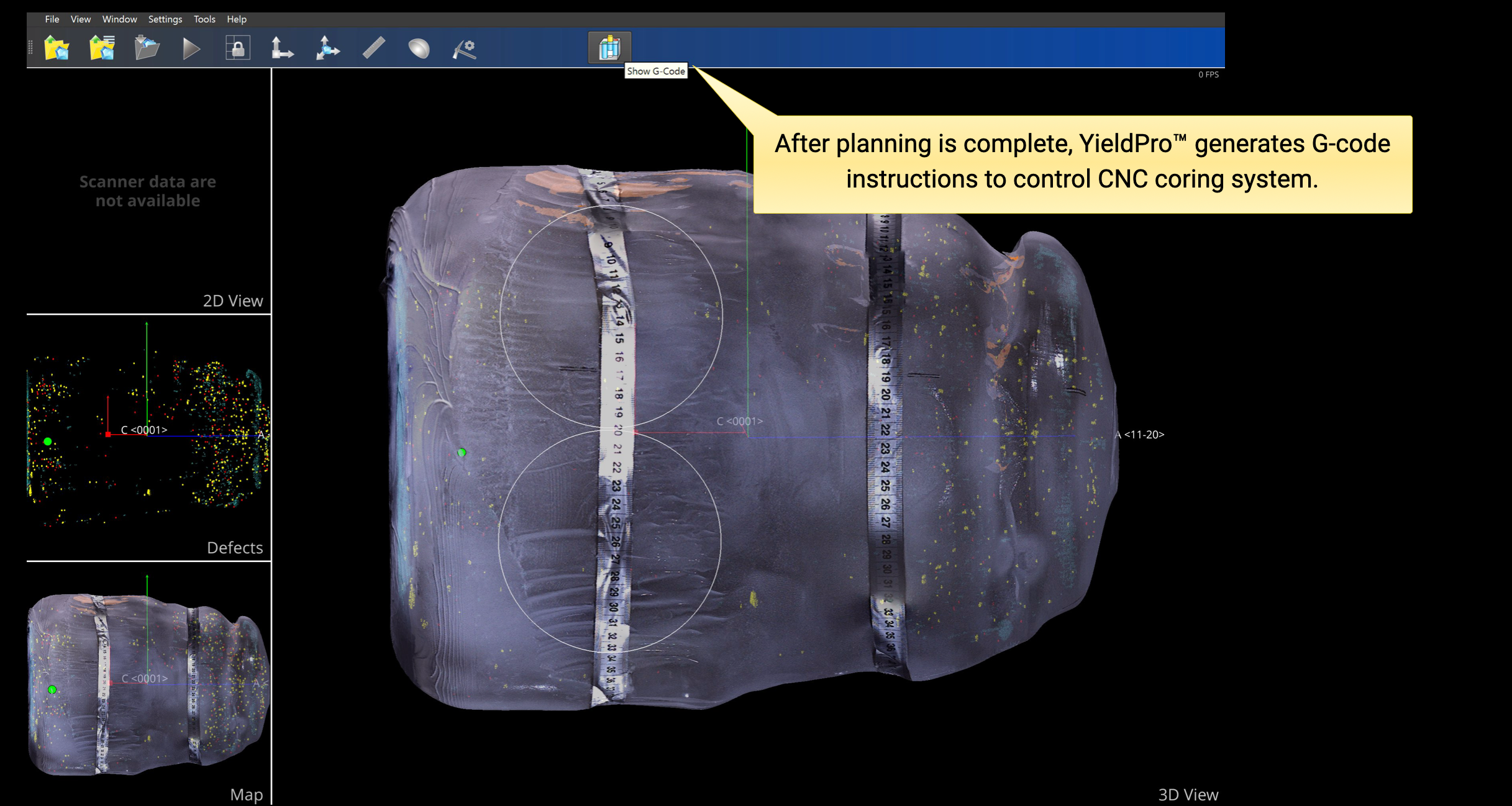

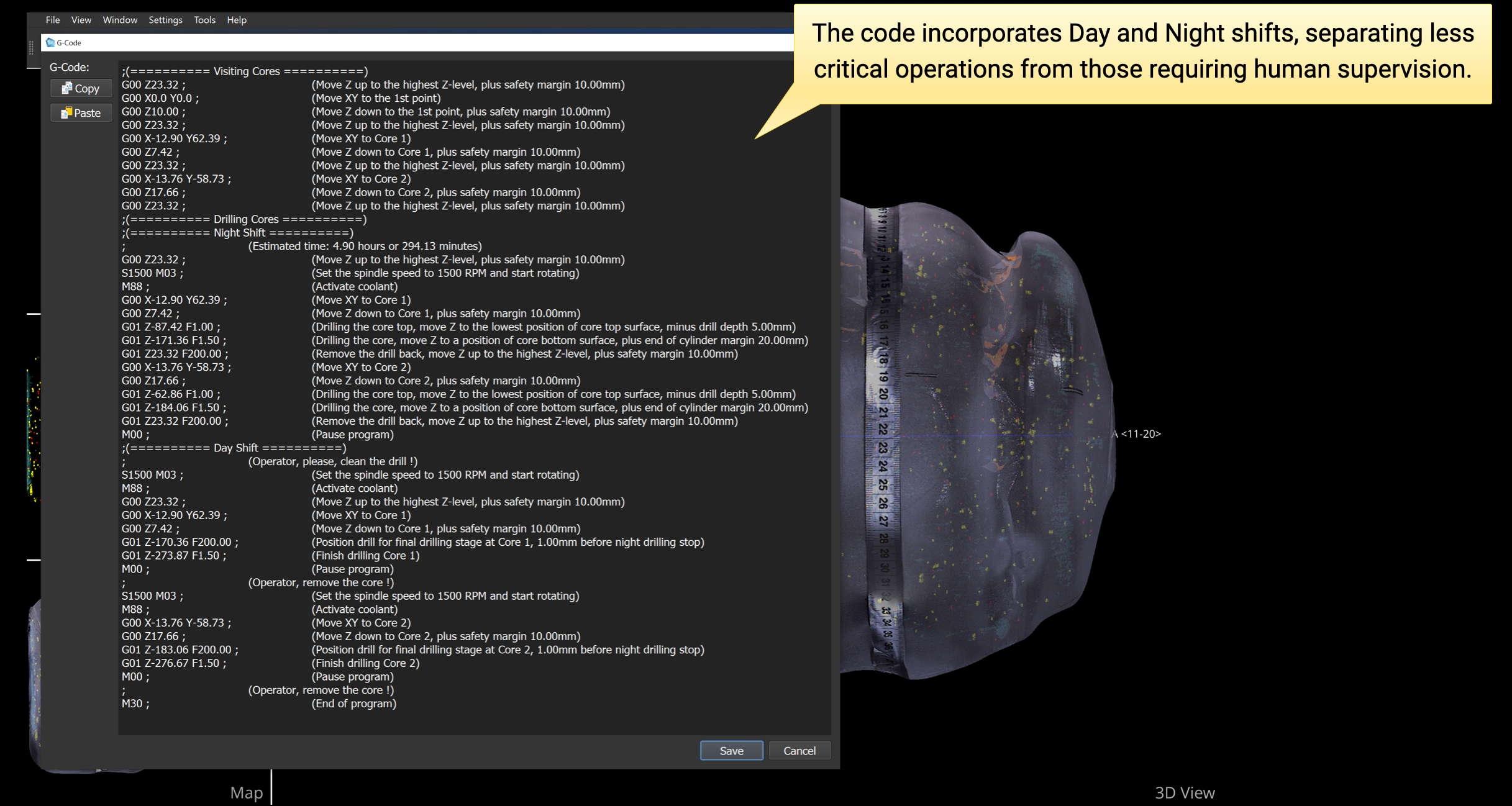

Export G-code to CNC coring machine

-

Configurable spindle, feed rate, safety margins and tool geometry

-

Seamless connection of physical crystal with its 3D digital twin

-

Generated G-code could be edited by operator directly in the YieldPro™ or other devices

-

Tested on industry-standard CNC controllers

-

Traceable workflow from digital analysis to machine execution

Complete reports in one click

-

Generate clear, consistent PDF reports for crystal quality and yield

-

Capture publication grade screenshots for presentations and marketing

-

Share 3D twins with partners, customers and colleagues – via email, Teams, or cloud

Integrate seamlessly into your workflow

-

Scientific Visual offers training and consulting services to help set up grading criteria, analyze production data and refine cutting strategies. Contact us to discuss integration with your existing equipment and IT infrastructure.

-

Need help in adding specific end-items from .DXF or other CAD files? We are here to support you.

- The software is available in English, Français, Deutsch, and 简体中文

Frequently Asked Questions

Is the software available only with Scientific Visual scanners?

No. YieldPro™ is the front-end software used on Scientific Visual scanners, but it can also be purchased as a standalone product.

In standalone mode, you can use the models received from others and process them in the same way—creating coring plans, wafering layouts, yield estimates, and reports.

Customers who order inspection services from the Scientific Visual laboratory use YieldPro™ in such mode to review their scan results and prepare cutting plans independently.

There is no difference between the embedded and the standalone versions.

What licensing options are available?

Choose between annual subscription or perpetual license—both include onboard training, updates, and support.

Do you provide training or workflow integration support?

Yes. We provide onboarding sessions, workflow optimisation support, and QC integration guidance.

Apart of software developers, our team includes professional scientists and crystallography specialists. This combined expertise, spanning instrumentation, crystal physics, and process engineering, enables us to support customers end-to-end – from debugging the crystal growth to processing optimisation.

What are PC requirements?

The below system requirements are for the most recent version of Yield-Pro.

Operating system:

-

Windows 10 or newer

Processor:

-

Minimum: 64-bit dual core, 2GHz

-

Recommended: 64-bit quad core or higher

Hard Drive:

-

Minimum: 2 GB free space

-

Plus: Additional space for each model file (20-200 MB for a typical model)

Memory (RAM):

-

Minimum: 8 GB

-

Recommended: 16 GB or more

Graphics Card:

-

Minimum: 6 GB VRAM, supports OpenGL 3.0