Overview

Scientific Visual helps to highlight and identify defects added at each stage of your sapphire or glass production, unveils the cause of the defects and advises how to eliminate them.

How it helps you

1. We give you an overview of quality losses in your production by measuring defects after each key production stage. Most losses can be avoided, for example by optimal annealing, or optimizing slicing and polishing. We are able to advise you on the extent and causes of these problems and how to fix them.

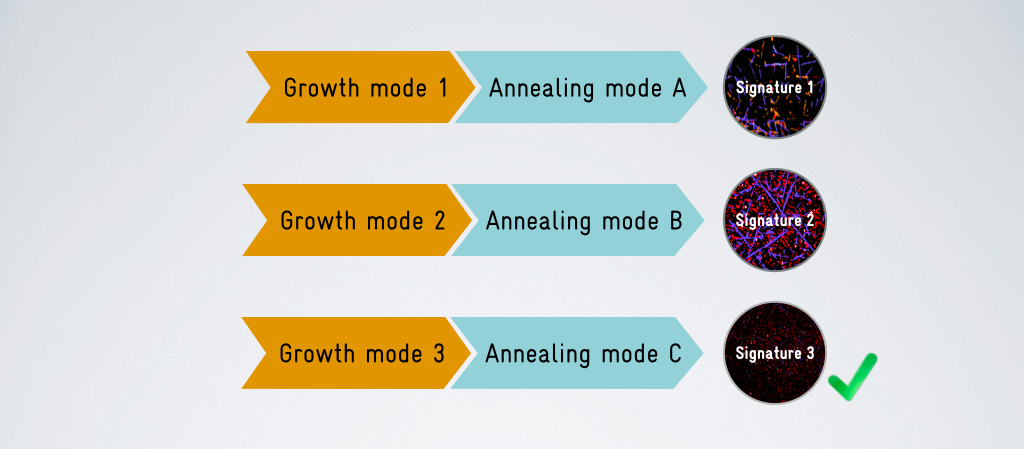

2. You will be able to optimize production parameters (temperature, incoming powder, annealing mode) by measuring their impact on defects and yield. You can effectively measure whether your process tuning efforts are bearing fruit.

3. The technology allows you to unveil long-time trends in the quality of produced material and fingerprint the various deviations in your process. This information can then be shared with customers to show that you always ensure that you meet the highest technical standards every time.

Batch Quality Signature™

Batch Quality Signature™ is a quantitative approach to revealing repeatable defect patterns both in unpolished and polished sapphire pieces, and establishing how these patterns are influenced by your production parameters. It is an important tool for production managers permitting them to assess production quality accurately and objectively and to eliminate costs. The results are also valuable for senior management and stakeholders who need to hold production managers accountable for end of line results and costs.

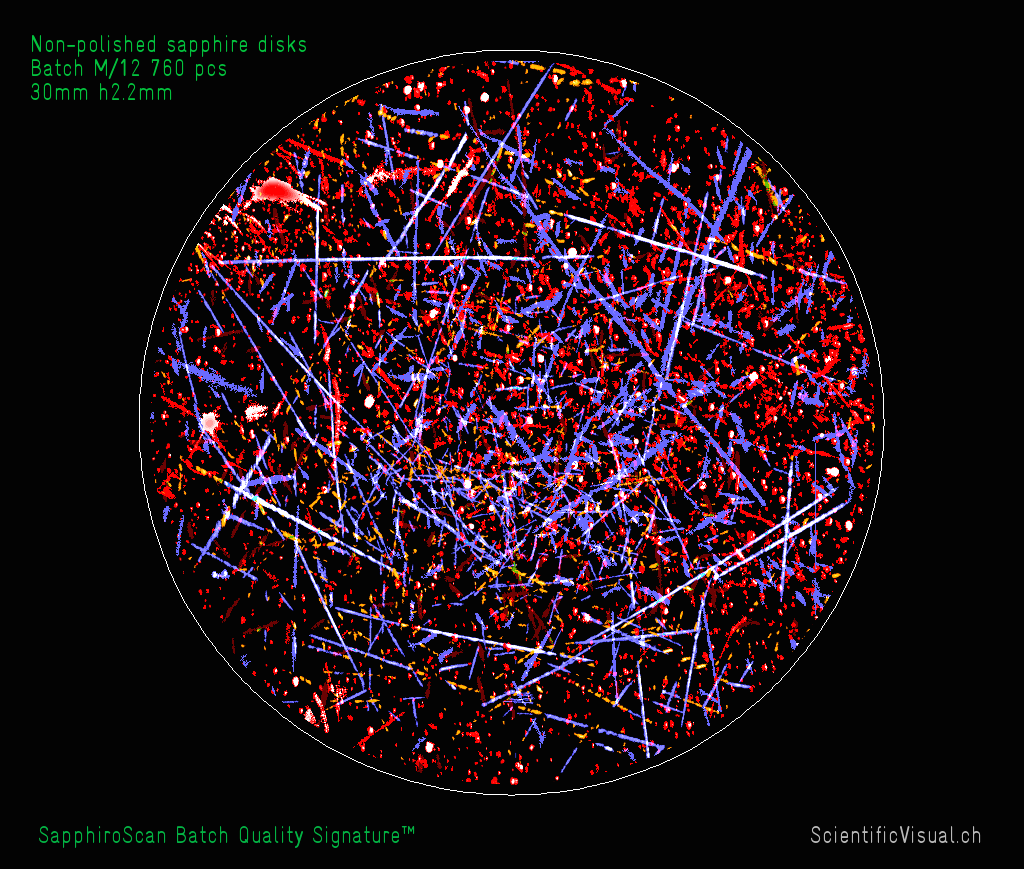

Batch Quality Signature™ is the superimposition of defect patterns recorded in individual pieces from the same set, for example those annealed with specific parameters, or originating from a specific supplier. Imagine if you could look through a set of hundreds of sapphire pieces joined together, and being able to see all defects in them at once, prior to polishing. With SapphiroScan™ software you now can. It enables the visualization threshold for each defect type to be altered and for the resulting image to be more or less ‘sensitive’ to specific defect types.

In this example we superimpose 760 non-polished sapphire watch covers :

SapphiroScan™ Batch Quality Signature for 760 non-polished sapphire watch covers. Colours stand for different defect types; white level represents defect visibility.

SapphiroScan™ Batch Quality Signature can be recorded cost effectively at intermediate production stages – with ‘as cut’, lapped/ground, or polished pieces – unlike traditional inspection which is performed after polishing to transparency.

How it works

Batch Quality Signature is recorded and electronically stored on the SapphiroScan™ scanner, it recognizes material defects in non-polished sapphire. To be statistically valid, a batch should contain several hundred pieces. Several batches are taken at various production stages, and the results recorded to produce a signature.

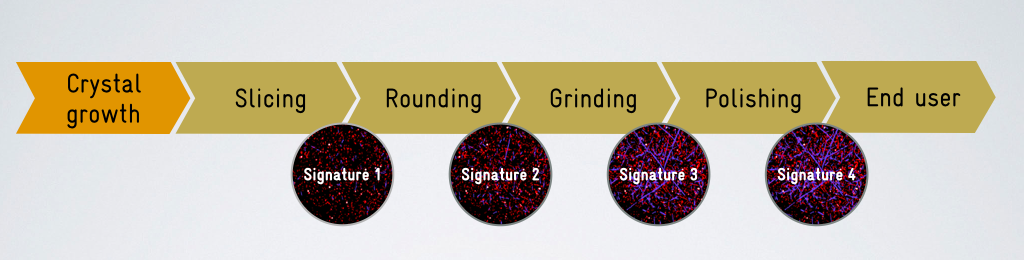

Batch Signatures taken at various processing stages

Based on the evolution of the defect pattern through production stages the technology reveals the nature of the defects. We are then able to provide advice on optimizing your process and how to decrease waste and therefore processing costs. Scientific Visual’s laboratory is equipped with latest SapphiroScan™ automatic scanners available for both round and rectangular sample testing.

QC services currently being offered covers the following:

| Pre-forms | Round or rectangular wafers / disks |

| Material | Sapphire, spinel, mineral glass |

| Surface | ‘As cut’, lapped/ground, or polished |

Scientific Visual runs inspections at its facilities in Lausanne, Switzerland. The results are delivered in electronic form. Test batches are shipped by post or can be picked up from Scientific Visual’s office in Lausanne. For enquiries about the inspection of other materials – please contact us.

Get a quote

To request an offer, please contact our sales by phone or by email:

- +41 79 217 12 10

- sales@scientificvisual.ch