What is it

CarrotScan is a technology allowing to scan carrot-shaped sapphire crystals 22-62 mm in diameter, and accurately map its defects, regardless of their type, size, and location, before costly processing stages.

It is the most accurate advanced defect mapping technology, optimising Verneuil sapphire with value analysis and sawing plan. For the first time you can measure defects, grade carrots objectively and feed defect statistics to the Production Team.

CarrotScan is used for scanning carrots and constructing its 3D models. Unlike manual quality inspection, it provides objective quality control and works independently of the operators’ skill.

Who benefits

CarrotScan is a part of Scientific Visual sapphire inspection flow.

It is used by Verneuil crystal growers and crystal sawing teams prior to carrot slicing. It allows them to eliminate defective material prior to expensive slicing stage, and re-route quality material according to application requirements. The process increases the production yield and lowers production costs for the watch industry.

For downstream inspection of already sliced sapphire disks (non-polished or polished) – use SapphiroScan.

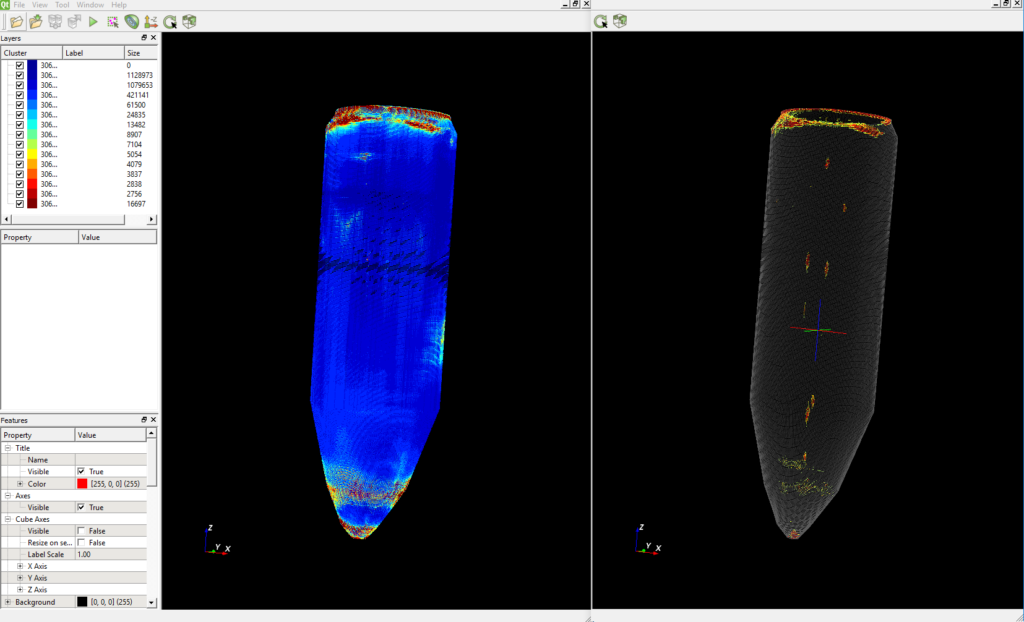

Defect pattern in non-processed Verneuil-grown carrot ⌀34mm, length 220mm visualised with CarrotScan™. The movie shows the transformation from “skin visualisation” to an inside view of the same carrot. Colour stands for defect density: from deep blue (non-defective material) to deep red (highest defectiveness).

Features

- Up to 15 um defects resolved

- Carrot diameters 22-62 mm

- Scanning time 2-5 min per carrot

- Indication of conformity/non-conformity for future slices (blanks, préparages)

- Carrot defectiveness is graded automatically according to pre-set quality thresholds

- 3D model with transparent skin to visualise internal defects

- Colour code for defect density: from deep blue (non-defective material) to deep red (high defectiveness)

- Free 3D viewer to exchange scans with partners and customers

- Objective defect statistics helps to find optimal growth parameters and get early warning of crystallisation process drift. See Process Optimisation > Quality Signature.

- Considerably increases material usage with a little increase in efforts

Technology

The patented process developed by Scientific Visual involves confocal tomography in optical liquids. It is performed quickly and automatically without the need for pre-processing the carrots. Each carrot (or carrot section) is then classified according to predefined quality thresholds, thereby eliminating the parts with too many defects according to the requirements of each watch brand.