YieldPro™

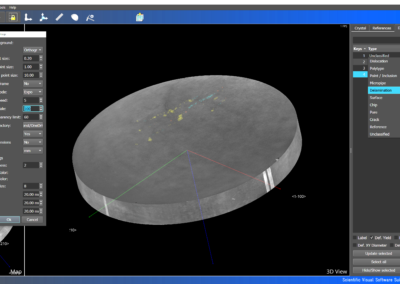

The software enables metrology data to be displayed in 3D, helping to identify defective areas and estimate their size. It is used in the semiconductor industry, particularly for IC quality control and failure analysis, as well as in the growing, processing and trading of industrial crystals.

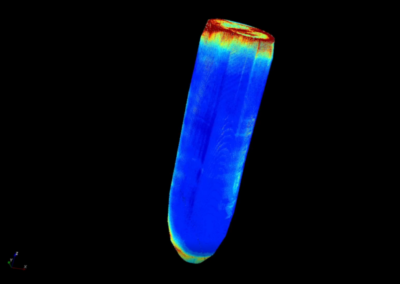

In Scanning Acoustic Microscopy (SAM)

- Visualise SAM scans as detailed 3D models

- Export X-scans to 3D model

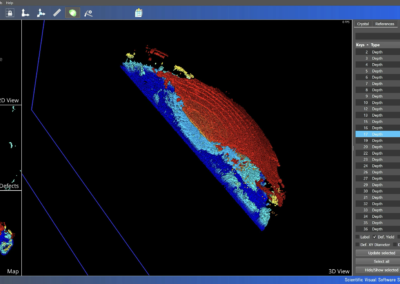

- Visualise depths and signal intensity with color coding

- Measure distances in 3D

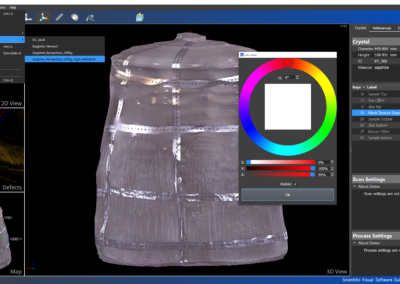

- Edit the 3D model to remove unwanted elements and highlight relevant areas

- Compare layers for failure analysis

- Dissect the 3D model and visualise the cross-sections

- Share 3D models with teams and customers

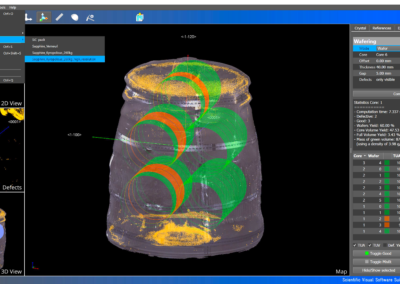

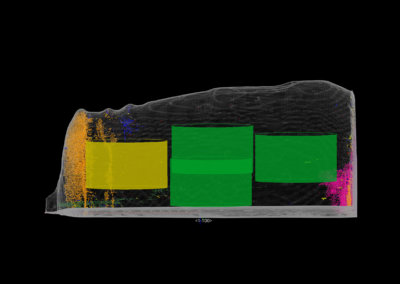

In Optical Tomography

- Visualise in 3D volume defects and crystal skin with texture

- Compute yield of the crystal for specific application (how many end-items you will get)

- Plan new cores along crystal axis or an oblique direction

- Estimate defect-free length of each core

- Simulate wafering or end-item cutting and predict their quality

- Maximise wafering yield with “Smart Wafering” feature

- Generate G-code for CNC coring machines

- Share 3D models with teams and customers