SapphiroScan™

Automatic workstations for non-polished and polished sapphire watch glass inspection. SapphiroScan™ allows early detection of defects and ensure that only suitable high quality materials enter the value chain. Unlike human inspection with the naked eye, SapphiroScan™ operates to an objective standard and ensures quick diagnostic feedback during the production stages.

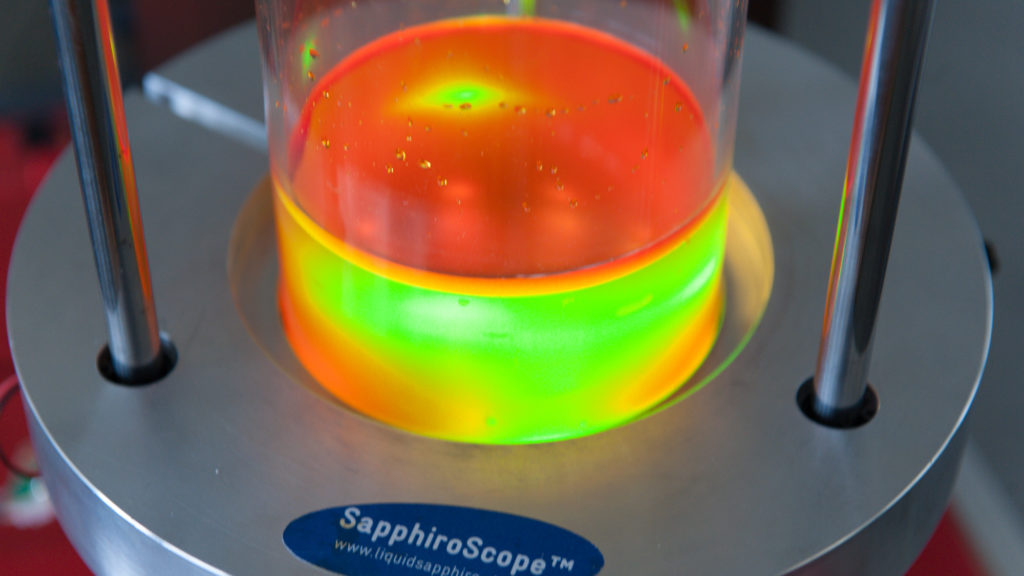

SapphiroScope™

An integrated quality control solution for semiconductor rodes prior to the wafering stage. A 3D model of defects is generated by reconstructing 2D slice-images from an axial scan through the controlled sapphire pre-form. The user has the option to rotate the 3D model, scan axially through the core volume, and then visualize the cross-section at any position along the core-axis.

Consumables

Self-cleaning cartridges with immersion liquids and replacement parts for Scientific Visual equipment. To order a new set please contact us quoting the serial number of your device.

Services

Scientific Visual analyses samples of non-polished sapphire, spinel, YAG or mineral glass using the above techniques to provide you with defect distribution figures, 2D slice-images or a 3D model of the defects in your pieces. The service is ideal for manufacturers who wish to exclude flawed areas of crystals prior to cutting or to analyze pre-forms which require costly processing.