Watch brands often inscribe logos or messages on sapphire windows of their watches. In some windows, the laser engraving process turns out to be unstable. Scientific Visual reports the identification of invisible defects that are responsible for this issue.

The watch industry quality standard requires a flawless engraving process without any observable defects. The flaws, if any, must be small enough to elude the customer eye, or be oriented so that they are invisible. Identifying defects affecting the engraving process of a sapphire window is much more difficult than identifying ordinary sapphire defects because even an optically clean crystal that passes quality control may contain invisible defects.

In May 2021, Scientific Visual, a sapphire quality think-tank, has been approached by a customer engraving patterns on the polished sapphire disks (préparages). While some patterns were created successfully, in other samples, the laser beam suddenly deviated, destroying the neighbouring sapphire area. In such a case, the engraved window was discarded, and a new one had to be produced. The problem appeared randomly and affected a substantial number of the processed samples. At the same time, the customer quality control has not revealed any material defects in the préparages intended for the processing.

Scientific Visual was mandated to identify the origin of the problem and to find a solution.

1a 1b

1b

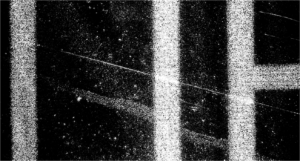

Fig 1a (left): Image of a miscarried inscription. High brightness areas show inscription defects, that are visible with a naked eye.

Fig 1b (right): Same area with underlying crystal defects visualised by Scientific Visual.

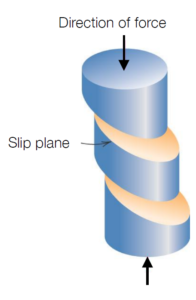

It appeared that the issue was caused by shear dislocations. It is an atomic size defect – a movement of a large number of atoms in response to applied tensile or compressive stress. Atoms from one of the surrounding planes break their bonds and re-bond with the atoms at several planes apart. Each dislocation results from the movement of many atoms along the same slip plane (see inset).

Shear dislocations were initially present in the préparages. They locally altered the photo-elastic properties of sapphire crystal so that the interaction of laser light with these decayed areas lead to uncontrolled destruction of the material around.The dislocations originate at the sapphire growth or cooling stage. Although they are present in different growth methods, such defects are more frequent in Verneuil-grown carrots, where they are caused by thermal stress during the carrot growth and annealing. In the latter case, the shear planes could appear later, already at post-growth stages, when the carrot crystal “relaxes.” The combination of both causes is also possible.

Such atomic size defects cannot be observed with conventional optical methods (Fig 1a). Nevertheless, Scientific Visual technology identifies such defects and reveals how underlying shear dislocations were responsible for the failure of the inscription (Fig 1b).

Mapping such defects within a sapphire window provides Scientific Visual’s customer with two solutions. It could either choose to discard sapphire windows containing shear dislocations; or use defect position data to orient the crystal prior to inscribing to avoid defective areas.

Irrelevant to the defect origin, knowing the precise location, morphology, and origin of defects is crucial for keeping production yield competitive. The quality control tools developed by Scientific Visual reveal hidden defects in unprocessed crystals before they enter the costly production stage. They also help to scientifically fine-tune the crystal processing and visualize production quality trends by accumulating defect statistics over time.

Scientific Visual mission is to empower every crystal manufacturer to achieve this important milestone.

Download: Press release in English, PDF

Shear dislocation principle

Even when the applied stress is tensile, shear components exist in directions other than parallel or perpendicular to the force direction. For a crystal in tension, the slip will occur along the most favourably oriented planes. In the sapphire hexagonal crystal lattice, it is r-planes, oriented at 115.2° to the crystal c-axis.